PRODUCT DEVELOPMENT

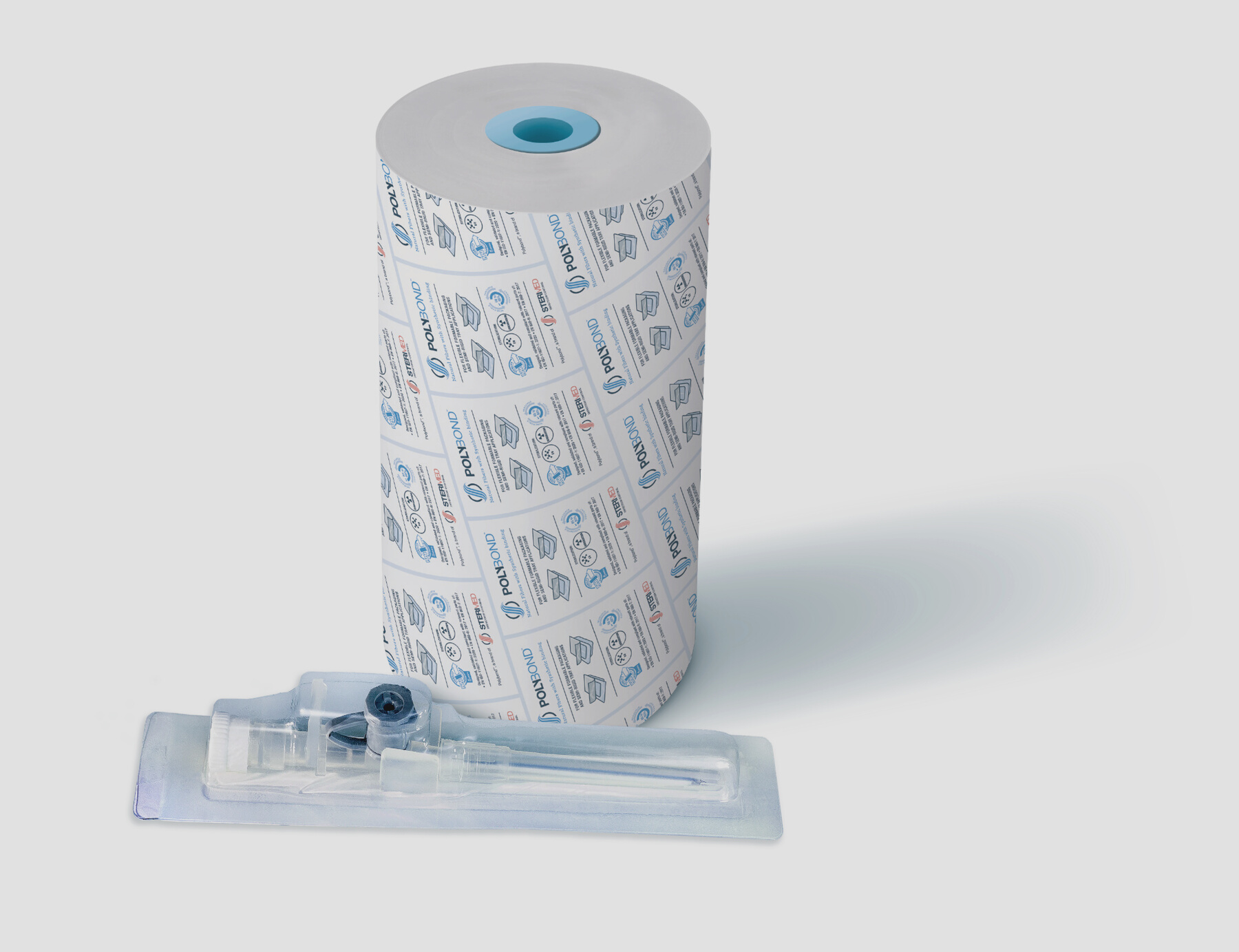

Polybond was developed by the Innovation Teams in Palalda, based on the latest generation of Polybond reinforced cellulose-based material!

The development of the product took several years as it included not only the creation of this new reinforced paper base but also the formulation of a high-performance heat sealing layer.

Thanks to the expertise of the porous web development teams and of the formulation development teams, Polybond® CGP was born!

POLYBOND CGP 85

A unique sustainable for most rigid packaging applications!

Polybond® CGP is mainly made from renewable resources and 70% bio-sourced carbon with solvent free technologies which makes it a great sustainable solutions!

With Polybond® CGP, it's up to 35 % less plastic in every rigid pack!

Polybond® CGP is also very attractive to our customers as it is a far less expensive alternative to the Tyvek® materials, not to mention the very advantages of our Polybond® products: Strong protection + Excellent sealing performance + Clean peel for aseptic presentation!

PRODUCT DEVELOPMENT

Polybond® Header Bag was long awaited by both our customers and by ourselves at Sterimed!

For a long time, Sterimed wanted to create a Header Bag solution without a Tyvek® window, but none of our converting partners were able to do it.

And then, the SPS Medical team joined the Sterimed Group!

Together, the Innovation team in Palalda and the Process team in Coulommiers, by combining their expertise and skills, managed to create Polybond Header bags in less than a year!

What a great achievement and a proof that Innovation comes from us togeher as one team!

POLYBOND HEADER BAG

The most sustainable header bag on the market, 1st header bag without the plastic Tyvek window.

The breathable window is made of Polybond® BGP, cellulose-based reinforced web made of 66% bio-based carbon instead of the good old all-plastic Tyvek®.

- Solvent-free

- Optimized end-of-life processability

- Compostable & biodegradable breathable window

- Controlled and reliable supply chain

SUCCESSFUL PRODUCT LAUNCH

EVENTS

- Pack Expo (USA)

- Compamed (Germany)

MAGAZINES

- DeviceMed - Fr and De issue

- Healthcare Packaging

- Medtech Innovation

Press Release, Interview

Advertisements

ONLINE